Challenge

Thermometers are normally installed in all coolers and freezers. To create a temperature log, employees will read the temperature from the thermometer daily, and write the readings on a piece of paper, which is kept as a log to be shown to government agencies inspecting the business.

Temperatures in coolers and freezers can increase to unsafe levels if the door is left open, or if the cooler or freezer does not operate correctly.

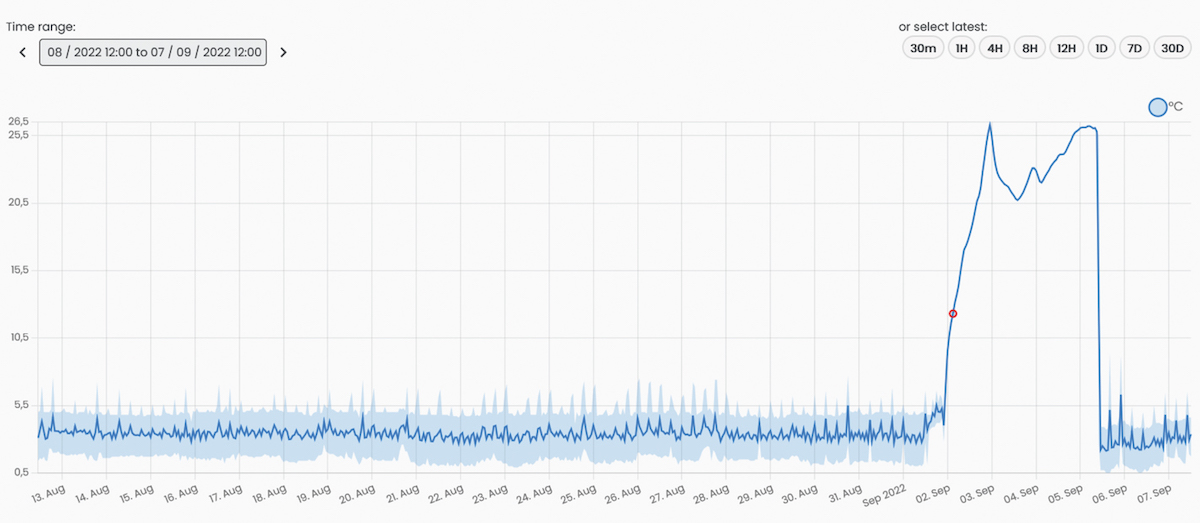

Manually logging of temperatures is a time-consuming task, but also inefficient to detect possible issues with the cooler or freezer. If a cooler is broken, it may not be detected until the next day’s inspection that temperatures are too high, and food is spoiled.

A temperature log on a piece of paper can easily get lost and can be manipulated by employees.

Another issue with logging temperatures on coolers and freezers is that they have automatic de-icing functionality that makes the temperature go higher for a period of 30 to 60 minutes.

Product brochure

Find the perfect sensor solution

Solution

Neuron temperature sensors are installed in all coolers and freezers. These sensors automate cooler and freezer monitoring. They measure the temperature every three seconds and create an electronic logbook with measurements every few minutes.

Alarms to employees will be set in the Neuron App to notify them if the temperature has been too high for a long period. With this alarm, employees can act before food spoils.

The Neuron IoT system will create a log of all measurements for the previous twelve months. This log cannot be manipulated and can be shown to management and inspectors.

What you get

- Continuous cooler and freezer monitoring

- Measurement every three seconds – for 10 years

- Easy mounting with cable tie – one sensor per cooler and freezer

- Automatic temperature log creation

- Alarms to employee’s mobile phones or computers if irregular temperatures occur