Challenge

Most industrial vehicles have a built-in engine hour meter. Maintenance staff is used to collect data from this hour meter and plan maintenance based on how many hours the vehicle has been running.

Manually collecting hour meter values can be time-consuming. The vehicle must be located and not used in a critical work task for the maintenance staff to access the hour meter value.

Manually collecting hour meter values means a person will look at the hour meter value, write it on a piece of paper, get back to a computer, and enter the hour meter value into a software to update an electronic log. Manual processes means there is a risk of human failure in all of the steps required, that would lead to the wrong hour meter value to be registered in the log. Such errors can lead to lack of maintenance at the right time, or planning and performing maintenance when it is not needed.

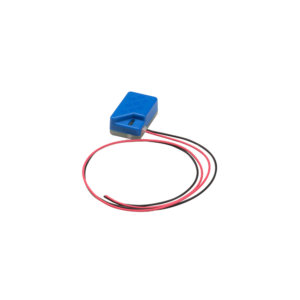

In areas with strong magnetic fields, such as aluminium smelters, electromechanical counters will struggle to count correctly. The Neuron Hour Meter has no mechanical parts and has no issues with strong magnetic fields in an aluminium smelter.

Product brochure

Find the perfect sensor solution

Solution

An IoT engine hour meter will constantly monitor the ignition status on the vehicle and count how many hours it has been on since the sensors was installed.

The hour count value will automatically be transferred to maintenance planning software, both when the vehicle is in use and when it is parked.

Vehicle maintenance can be planned to the correct time.

What you get

- Neuron Hour Meter installed in the vehicle

- Neuron Gateways that collects Neuron Hour Meter value when the vehicle is in the vicinity.

- Electronic log of when vehicle is used and the accumulated hours the vehicle is in use without risk of errors from manual data collection.