Challenge

Without condition-based maintenance, maintenance is usually performed on regular dates or hours. Some assets will fail before the scheduled maintenance; others will be taken out of production for maintenance too early.

Data provided by asset vendors or automation systems is often insufficient to determine if maintenance is needed.

Assets of the same type but with different ages, models, and make may have different capabilities to provide data that shows the state of the asset.

Product brochure

Find the perfect sensor solution

Solution

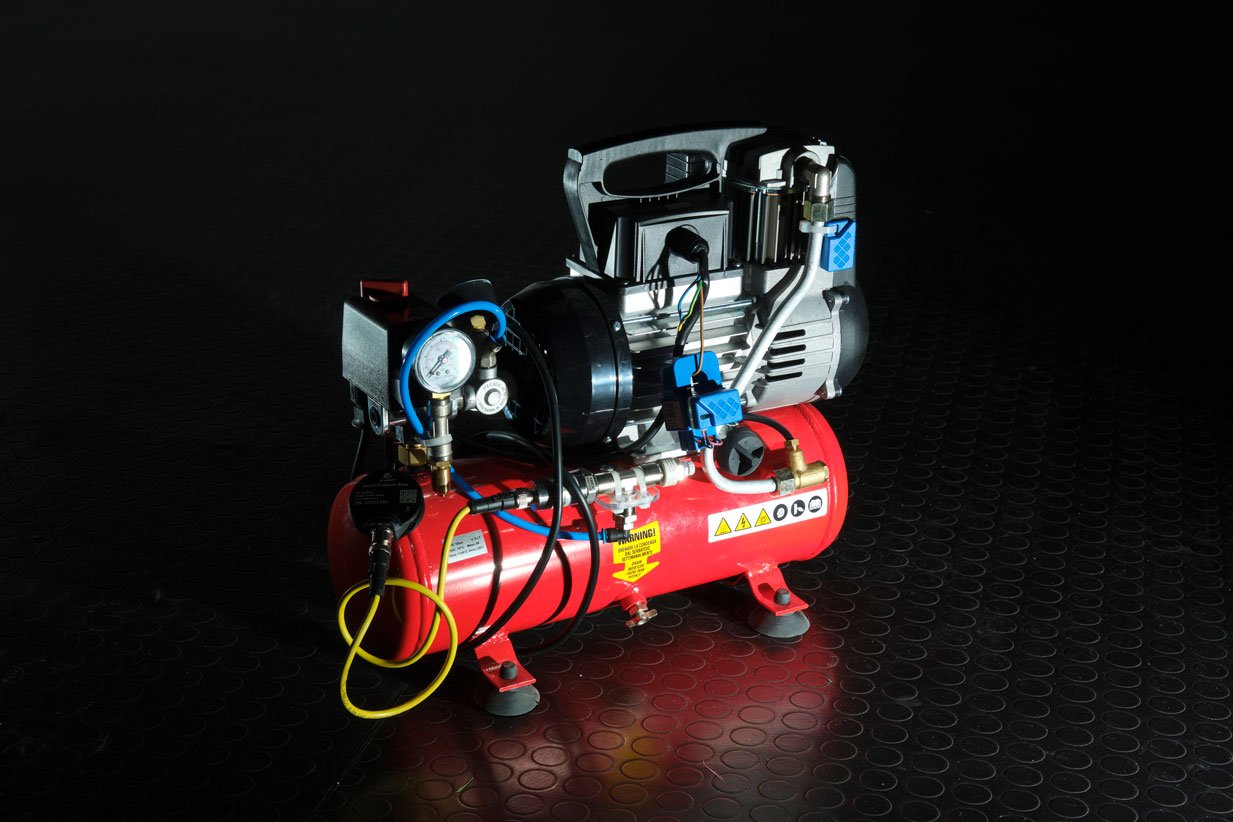

Vibration, temperature, and current sensors are all great tools to understand if an asset needs maintenance.

With sensors that monitor continuously, it is easy to understand what the normal state of an asset is.

Sensors detect irregular operation of an asset when sensor data such as vibration, temperature, or current consumption are higher than normal.

Maintenance operators will then focus their efforts on assets with irregular behavior instead of spending their valuable time on every asset in the production line.

What you get

- A Neuron Vibration sensor monitors both vibrations and surface temperature of an asset. With magnet mounting, it is easy and quick to install the sensor to start gathering data.

- A Neuron Ampere sensor continuously measures current consumption by an asset or a circuit. Comparing current consumption at similar conditions will be of great help to understand if an asset is struggling to do its tasks, indicating it needs maintenance.

- Alerts on irregular behaviour of the asset can be provided to maintenance operators on e-mail, SMS or push warnings for them to prioritize their job on assets that need their care.

- Less maintenance, and correct maintenance leads to higher productivity and a more efficient maintenance staff.

- Data from Neuron IoT sensors can be provided to any software for further analysis or storage by using API integrations from the Neuron Cloud.